Pelletizing solution with spheronizer technology

Modern shaping for improved effectiveness

The challenge in modern healthcare and beauty care, but also when using fine chemicals, is the production of compounds in modern dosage forms. Users want simple and smart handling at the same time. These advantages are particularly easy to derive from the use of (micro)pellets. So that you can meet your requirements for pellets in the desired quality, we use spheronizer technology in a targeted manner, which also has holistic process solutions in mind so that you remain flexible.

Pellet shaping with the spheronizer

Pellets at their best. With modern spheronizer technology and smartly combined solutions:

- process solution for optimal, round granules and (micro) pellets

- targeted API-release

- no unwanted effects by "dose dumping"

- well thought-out modular solution for clever combination of processes such as pelletizing, mixing and granulating

- avoiding product losses: in-house DIOlab for product and process development at the DIOSNA headquarters in Osnabrück

Start a successul laboratory phase with the Plug&Play table device and also use the DIOSNA expert network for qualified advice and support.

Good to know: The experts from DIOSNA, in cooperation with Gabler, map out the entire production process for you from the granulator to the extruder and spheronizer to the fluidised bed device and offer you solutions.

For your pellets at their best with DIOSNA know-how

Ideal for your laboratory batches: create optimal pellets using the DIOSNA spheronizer. The spheronizer ensures high-quality pelleting for the development of oral solid dosage forms, but also for use in the cosmetics industry and for the production of fine chemicals. The tabletop device saves space and is immediately ready for use via Plug & Play.

Spheronizer technology for a convincing result

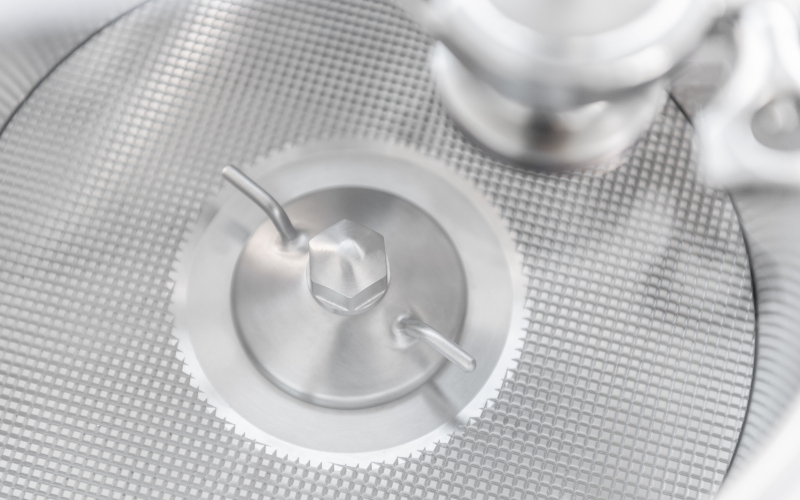

The rapidly rotating friction plate forms spherical pellets with a smooth surface, perfectly suited for subsequent process steps such as drying and coating. The finished product is then filled into sachets, stick packs or capsules, for example, and thus offers you variable presentation options.

Product focus thanks to DIOSNA technology

DIOSNA experts ensure easy operation so that you can fully focus on your product. The spheronizer is therefore easy to use. The extrudates are filled into the bowl via manual feeding and formed into pellets at the push of a button via manual or PLC adjusted to the specific product requirements. You will receive a product of outstanding and reproducible quality.

DIOlab Pharma

Smart module solution for modern and smart thinkers

Combine processes in a smart way by adding the laboratory mixer from DIOSNA to the spheronizer. The modular principle enables you to integrate the mixing and granulating processes into your laboratory work with just one basic machine, thus making your development work economical and resource-optimised.

To do this, simply exchange the spheronizer against the mixing bowl on the basic machine. However, the spheronizer can also be operated independently.

Modular P 1-6