The containment solution with our isolator technology

Essential for highly effective medicines

The highest safety and quality standards are the basis for the production of highly effective medicines such as granules, inhalates and tablets.

DIOSNA offers user-friendly containment solutions for research and development in the pharmaceutical industry to protect operators, products and the environment. Our experts will find the isolator that is tailored to your specific requirements.

Security and flexibility for your specific requirements

Containment is of paramount importance in the manufacture of oral solids due to the range of possible contamination areas. Strong regulation of the requirements for complex manufacturing processes are complicated by strict regulations. As a long-standing experienced supplier of pharmaceutical containment systems, DIOSNA offers a wide range of solutions to meet even stringent requirements such as OEB5.

Your advantages:

- Ideal for batches up to 5 kg

- Free-standing or "Through The Wall" installation

- Mixers, dryers and mills can be handled easily with gloves on

- Design up to the highest OEB level possible

- Units can be opened during process interruptions

- Open handling of materials inside the isolator

Get in touch with our experts and discuss your new containment solution according to the highest safety and quality standards.

Single-use Equipment as a flexible alternative

For the occasional handling of sensitive substances, we offer you a practical solution with flexible single-use bags and the corresponding interfaces. The single-use bags are attached to the machines via reusable valves, often using plastic retention valves. Alternatively, the machines can be equipped with flexible isolators that are individually designed and used specifically for campaigns. DIOSNA process systems can be adapted for use with soft isolators to ensure an adequate containment solution.

Contact experts

Containment in Research & Development

Especially in R&D, the installation of mixer granulators, fluidised bed systems or single-pot processors in isolators has proven to be a viable solution. These are particularly suitable for small batches. They also allow convenient handling of materials and system components and offer a high degree of flexibility for process adjustments at short notice.

Contact experts

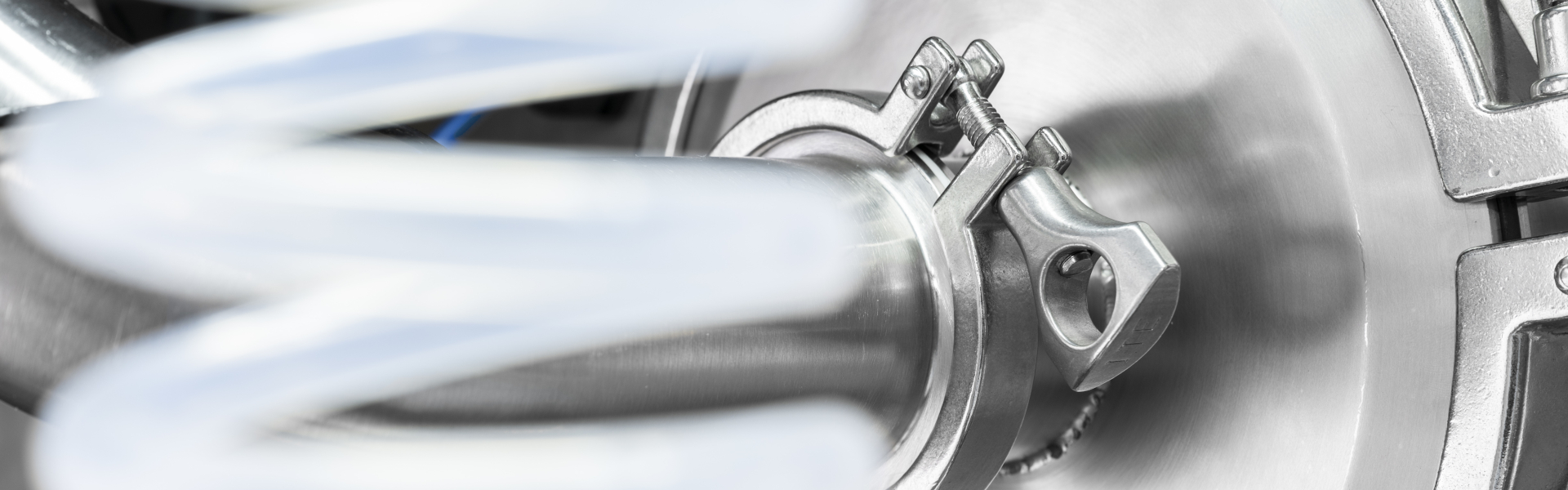

Smart transfer systems and individual design of DIOSNA isolators

The individual plant components can be opened almost at any time for sampling, which is a decisive advantage in the product development phase. The hermetically sealed isolators, which operate under negative pressure, guarantee maximum safety and are leak-proof despite manual operation. This is ensured, among other things, by special transfer systems for charging and discharging auxiliary materials and APIs. At the end of a process, the entire interior of the isolator can be decontaminated and is then ready for the next application. Together with DIOSNA, you can customise the interior of your isolator; optional scales, pumps or sieve mills are possible, for example.

Start planning!